Servo-pneumatics

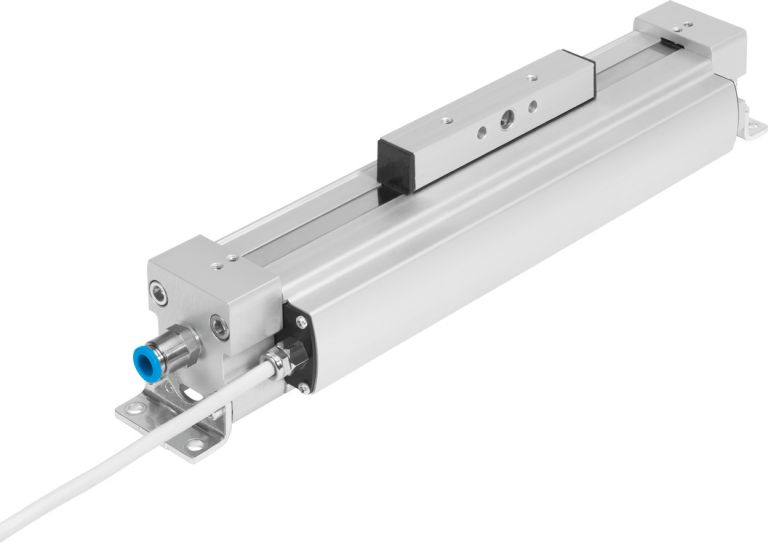

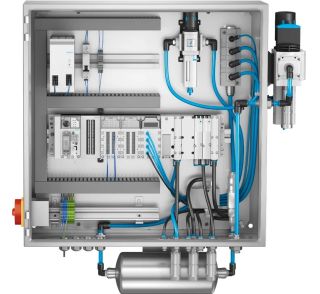

Ø At Festo, servo-pneumatics stands for controlled pneumatic positioning technology. Servo-pneumatics is always a system, which consists of a cylinder with displacement encoder, a proportional directional control valve and a position controller. With a servo-pneumatic system, a pneumatic cylinder can be moved to a preset target position in a position-controlled manner or generate a preset target force in a force-controlled manner.

Ø Servo-pneumatics is a "soft" positioning technology because air is a compressible drive medium. When the drive is in a controlled position, it can be pushed away by a correspondingly large external force. These systems are good value for money, especially for moving weights over 10 kg.

Ø As the global market leader in servo-pneumatic systems, Festo now presents the third generation of servo-pneumatic drive systems.

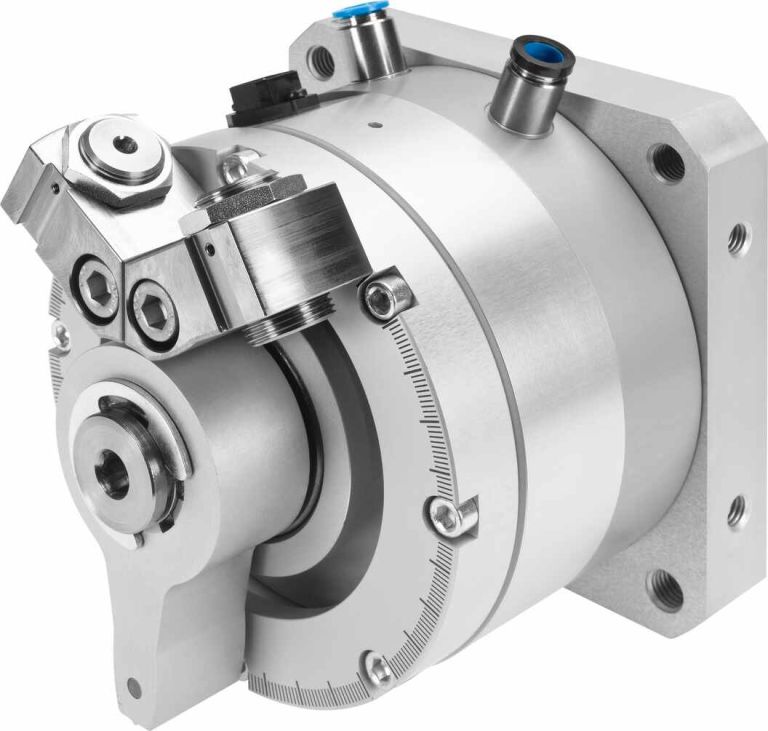

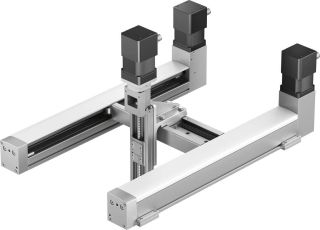

Ø Semi-rotary drive with displacement DSMI, DFPI, DDPC, DNCI, DGCI

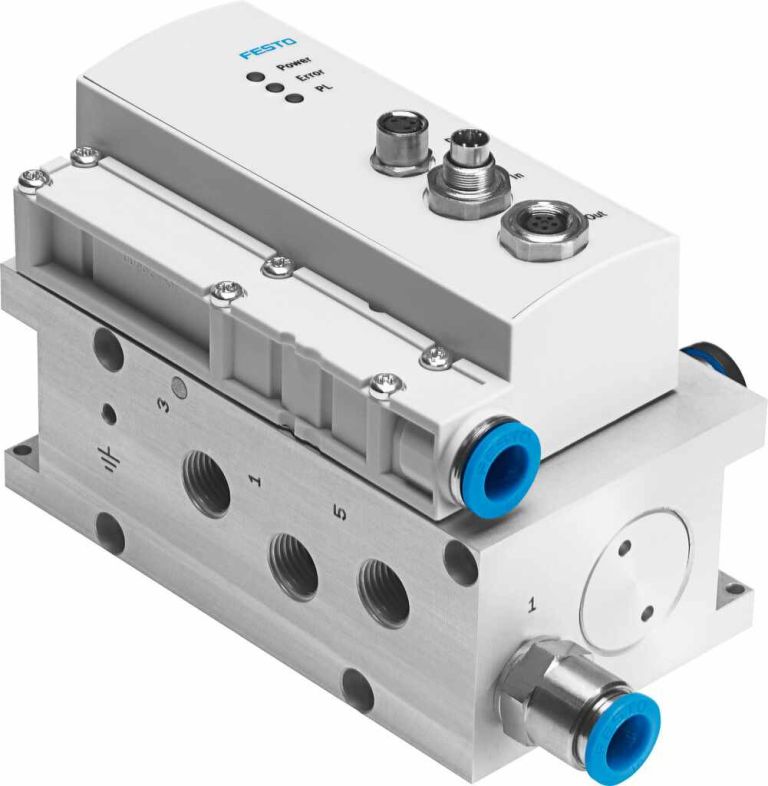

Ø Axis Controller CPX, SPC11, MME-MTS, MLO-POT, MPYE, VPWP, CASM, DADE

Ø Plug & Connecting cable FBS-SUB, KMPYE, KVI

Ø Pneumatic positioning and force control

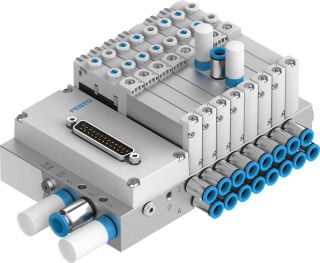

Ø A technology module of the terminal CPX

Ø Easy commissioning with Festo configuration tool FCT

Ø Automatically detects connected system components: valve VPWP, sensor interface CASM or the cylinder

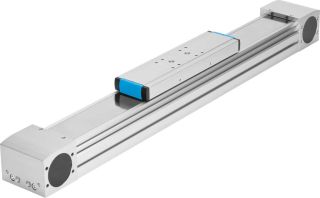

Ø Moves loads of 2 to 450 kg

Ø Controls forces between 30 and 4712 N

Ø High travel speed and long service life

Ø Plug-in connections