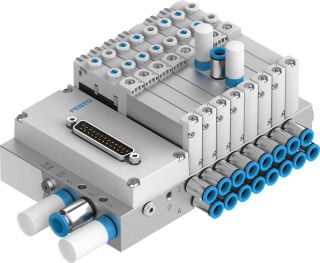

Compressed Air Preparation

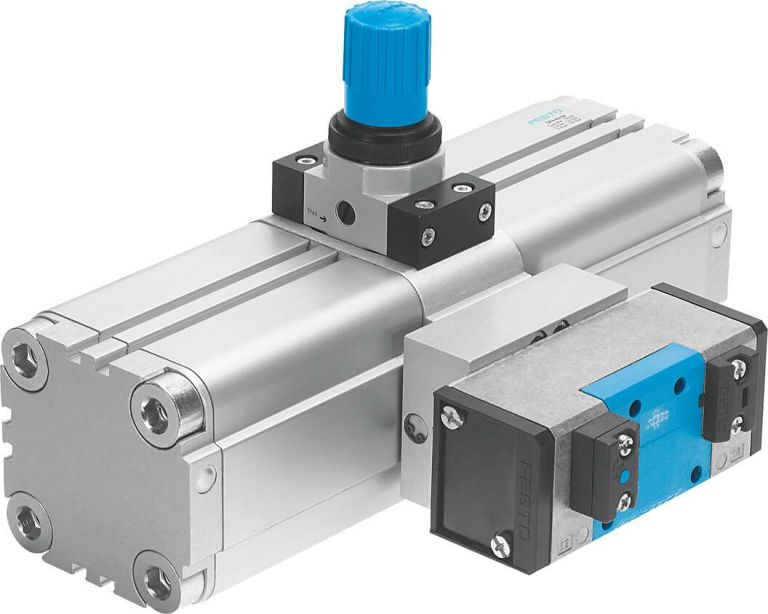

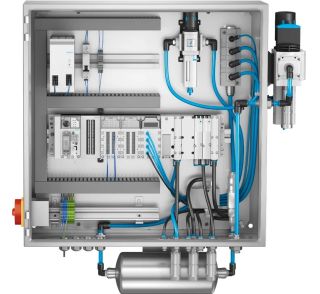

Ø Depending on the application, service units typically consist of a wide range of functional modules, such as a manual pressurisation and exhaust valve, a filter regulator and a branching module. At Festo, the most common combinations in the MS series are available from stock pre-assembled. In addition, with the configurator MSB of the MS series, complex service units can also be individually configured step by step, which is ideal for any application. These units are delivered fully assembled, pressure tested and therefore ready to install. As part of the Festo Core Range, these individual configurations can also be processed worldwide and are therefore quickly available. They are available in the three sizes MS4, MS6 and MS9 for a wide range of flow rates. Depending on the configuration, they are suitable for use in potentially explosive areas of zones 1, 2, 21 and 22 as well as with UL approval.

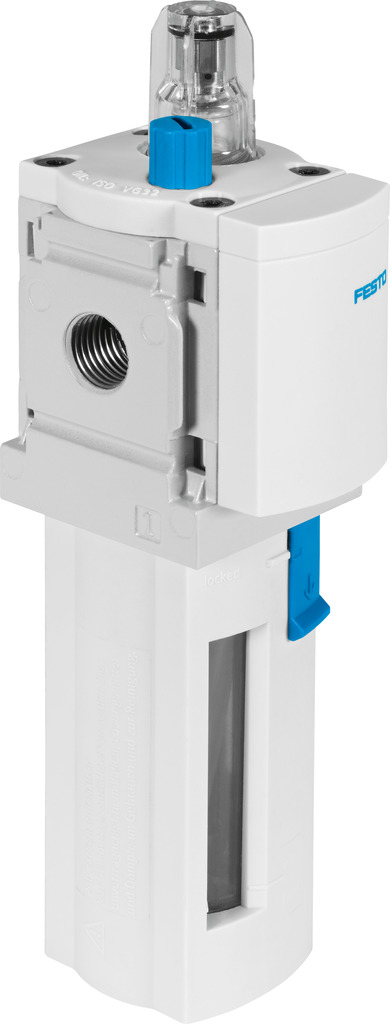

Ø Service unit LR, LFR, FRC, LRP, MS6, LOE, HE, FRM, LDM1, MSB

Ø Filter, regulator and lubricator functions in a single unit

Ø Size micro, mini, midi, maxi

Ø Size MICRO, MINI, MIDI, MAXI

Ø Port M5, M7, G1/8, G1/4, G3/8, G1/2, G3/4, G1, QS4, QS6, also available with NPT thread

Ø Pressure 0.5 ... 7 bar, 0.5 ... 12 bar

Ø Flow rate 110 ... 11000 l/min

Ø Pressure gauge

- With pressure gauge

- Without pressure gauge

Ø Grade of filtration 40 µm, 5 µm

Ø Condensate drain

- Manual

- Semi-automatic

- Fully automatic

Ø Plastic bowl with metal bowl guard